If you’re looking for help with a Site-Specific Safety Plan (SSSP), you’re not alone.

Many New Zealand contractors and builders are required to provide an SSSP for:

a new construction project,

a principal or client request,

pre-qualification or tendering,

or site access approval.

The challenge is that most SSSPs exist only as documents, not as tools that are actually used on site.

This guide explains how to create an SSSP that works in practice, not just one that ticks a compliance box.

What an SSSP Is Meant to Do (In Plain Terms)

A Site-Specific Safety Plan is intended to show how health and safety risks will be managed on a particular site, for a specific scope of work, at a specific time.

A working SSSP should:

reflect real site conditions (access, layout, environment),

reflect the actual work being carried out,

identify only significant site-specific hazards,

and be used throughout the life of the job.

Where many SSSPs fall short is not legal compliance — it’s practical use.

Why Many SSSPs Fail on Real NZ Worksites

1. They’re Generic by Design

Templates and copied plans often:

look professional,

include the right headings,

but don’t reflect the realities of the site.

This is one of the most common reasons principals push back on SSSPs.

2. They’re Created Once and Forgotten

Construction sites change:

work stages change,

trades change,

hazards change.

A static SSSP written at the start of a job quickly becomes outdated.

3. They’re Disconnected from Daily Work

If the SSSP:

sits as a Word document,

or is filed as a PDF,

or is only referenced during induction,

then it has little influence on what actually happens on site.

What Makes an SSSP Actually Work

A practical SSSP is not defined by its format — it’s defined by how it is used.

It Must Be Truly Site-Specific

A working SSSP reflects:

site access and traffic movements,

nearby hazards and interfaces,

the real sequence of work,

and the trades involved.

Generic plans fail this test immediately.

It Must Be Able to Change as the Job Changes

If updating an SSSP:

takes hours,

requires rewriting documents,

or means re-engaging consultants every time,

it simply won’t stay current.

It Must Be Available on Site

For an SSSP to influence safety:

workers need to be able to see it,

discuss it,

and refer to it during pre-starts, inspections, and planning.

If it lives in an office folder, it’s effectively invisible.

How an SSSP Becomes an Integrated Site Tool (Not a Tick-and-Flick Document)

One of the biggest weaknesses of traditional SSSPs is that they are isolated documents.

Even well-written plans often:

sit apart from daily site activity,

are never referenced again,

and don’t evolve as the job progresses.

A working SSSP avoids this by being integrated into how the site operates.

Integration Is What Stops an SSSP Being High-Level

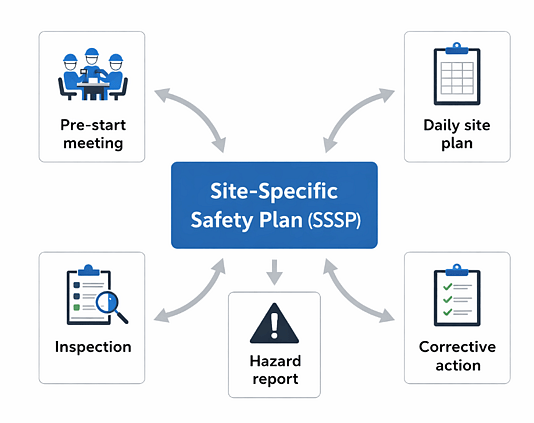

In an integrated approach, site-significant hazards identified in the SSSP are available during:

pre-start meetings,

daily site planning,

inspections,

hazard reporting,

and corrective actions.

The same hazards and controls are revisited repeatedly, not rewritten differently in each document.

Issues raised on site can be linked back to the original SSSP planning.

This creates continuity between planning and execution.

Why This Is Different from Templates and PDFs

This is not about ticking boxes or relying on default controls.

The difference is that:

hazards are identified deliberately,

controls are discussed and applied in context,

and those same hazards and controls are reused consistently across site activity.

Because the SSSP is connected to daily processes:

it is reviewed more often,

inconsistencies are easier to spot,

and changes on site naturally feed back into the plan.

That feedback loop is what keeps an SSSP relevant.

Common SSSP Problems — and Practical Ways to Fix Them

“Our SSSP Is Out of Date”

Cause: Static documents that don’t evolve with the job.

Fix: Use a structure where site information and hazards can be updated as work changes.

“Workers Don’t Follow the SSSP”

Cause: Workers don’t see it, or it doesn’t reflect reality.

Fix: Make the SSSP visible during inductions, pre-starts, and inspections.

“Updating the SSSP Is Too Expensive”

Cause: Reliance on repeated consultant rewrites.

Fix: Separate professional support from day-to-day ownership of the plan.

Getting Help with an SSSP in NZ: Your Main Options

1. Templates

Pros: Fast, low cost.

Cons: Generic, static, often criticised or rejected.

Templates can help you start, but rarely result in a robust, working SSSP on their own.

2. Consultants

Pros: Expertise, compliant structure.

Cons: Expensive to update, slow to change, often disconnected from daily site activity.

Consultants are valuable — particularly for review or complex risk — but relying on them for every update is rarely sustainable.

3. Integrated SSSP Systems

Pros:

Site-specific information captured once,

hazards and controls reused consistently,

accessible on site,

updates made as work changes.

Cons:

Requires a shift away from one-off documents.

For many contractors, this approach solves the biggest challenge: keeping the SSSP live and usable throughout the job.

What Principals and Auditors Actually Look For

Regardless of format, a strong SSSP should clearly show:

how site-specific hazards were identified,

how controls match the actual work,

how workers were informed and involved,

and how changes were managed during the job.

An integrated SSSP makes this easier to demonstrate because planning, communication, and follow-up are connected.

Making Your SSSP Sustainable (Not Just Compliant)

The biggest shift most contractors make is moving from:

“We need an SSSP for this job”

to:

“We need a way to keep our SSSP relevant for the life of the job.”

That’s what principals, clients, and auditors increasingly expect — not just a document, but evidence that safety was managed as work happened.

Need Practical Help Creating an SSSP?

If you’re looking for a way to:

create genuinely site-specific SSSPs,

keep them updated as work changes,

link them to inductions, pre-starts, inspections, and site activity,

and avoid starting from scratch each time,

then using an integrated New Zealand Site Specific Safety Plan (SSSP) system that is built from real site risks and connected to inductions, pre-starts, inspections, and daily site activity is often more effective than relying on static templates or repeated rewrites.